In the fast-paced world of modern manufacturing and logistics, efficiency and speed are paramount. Every aspect of the supply chain, from production facilities to distribution centers, plays a vital role in ensuring products reach consumers quickly and in pristine condition. One often-overlooked hero in this process is the humble strapping machine, a piece of equipment that revolutionises the way goods are secured for shipping and storage.

The Basics of Strapping Machines

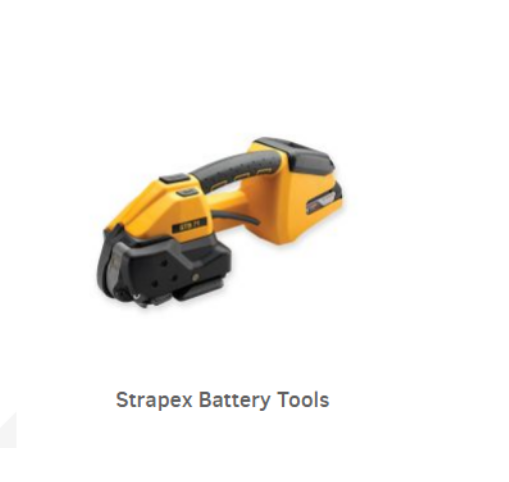

Strapping machines, also known as banding machines or bundlers, are devices designed to securely bundle together a variety of products using straps or bands made of materials such as plastic, steel, or polyester. These machines are invaluable across numerous industries, including manufacturing, agriculture, and logistics.

Efficiency in Packaging

One of the most significant advantages of strapping machines is their ability to streamline the packaging process. Traditionally, manual strapping methods required considerable time and labor, leading to increased costs and the risk of human error. Strapping machines, on the other hand, automate this process, dramatically reducing the time required to secure packages. This increased efficiency translates to cost savings and enhanced productivity.

Versatility in Materials and Applications

Strapping machines are highly versatile and adaptable to a wide range of materials and applications. Whether you need to secure boxes, pallets, bundles of newspapers, or even heavy-duty construction materials, there is a strapping machine designed for the task. Different industries and packaging needs call for various strapping materials, and these machines can accommodate them all, from plastic straps for lightweight packages to steel straps for heavy-duty shipments.

Improved Load Stability

Ensuring load stability during transportation is crucial to prevent damage to products and reduce the risk of accidents. Strapping machines play a pivotal role in enhancing load stability by tightly securing packages, minimising the risk of shifting or damage in transit. This is especially important in industries where fragile or valuable goods need to be transported with care.

Cost-Efficient Packaging

Investing in strapping machines can lead to significant long-term cost savings. While the initial purchase cost may seem substantial, the reduction in labor costs, materials wastage, and damage to goods quickly offsets the investment. Additionally, the durability of strapping materials ensures that packages remain secure throughout their journey, reducing the likelihood of returns and replacements due to damaged goods.

Eco-Friendly Packaging

In an era where environmental concerns are paramount, strapping machines can contribute to eco-friendly packaging practices. Many strapping materials, particularly plastic straps, are recyclable. By using strapping machines to reduce the amount of material needed and ensuring packages remain intact, companies can reduce their environmental footprint and align with sustainability goals.

Safety and Ergonomics

Manual strapping can be physically demanding and pose risks to worker safety due to repetitive motions and potential strain-related injuries. Strapping machines not only eliminate these safety concerns but also enhance the overall ergonomics of the packaging process. Workers can operate these machines comfortably, reducing the likelihood of injuries and improving overall workplace safety.

The Future of Strapping Machines

As technology continues to advance, strapping machines are also evolving. Modern strapping machines often come equipped with advanced features such as automatic tensioning and cutting, making them even more user-friendly and efficient. Additionally, the integration of strapping machines into automated production and logistics lines is becoming increasingly common, further optimising the packaging process.

Conclusion

In a world where time is money, strapping machines are unsung heroes in the world of packaging and logistics. These versatile devices offer efficiency, cost savings, and improved safety, all while contributing to eco-friendly packaging practices. As industries continue to evolve, the role of strapping machines will only become more critical in ensuring that products reach their destination securely and on time. Whether you’re in manufacturing, distribution, or any industry that involves packaging, strapping machines are a valuable asset that should not be underestimated.